Automation Redefined: Efficiency and Precision in Tool Manufacturing

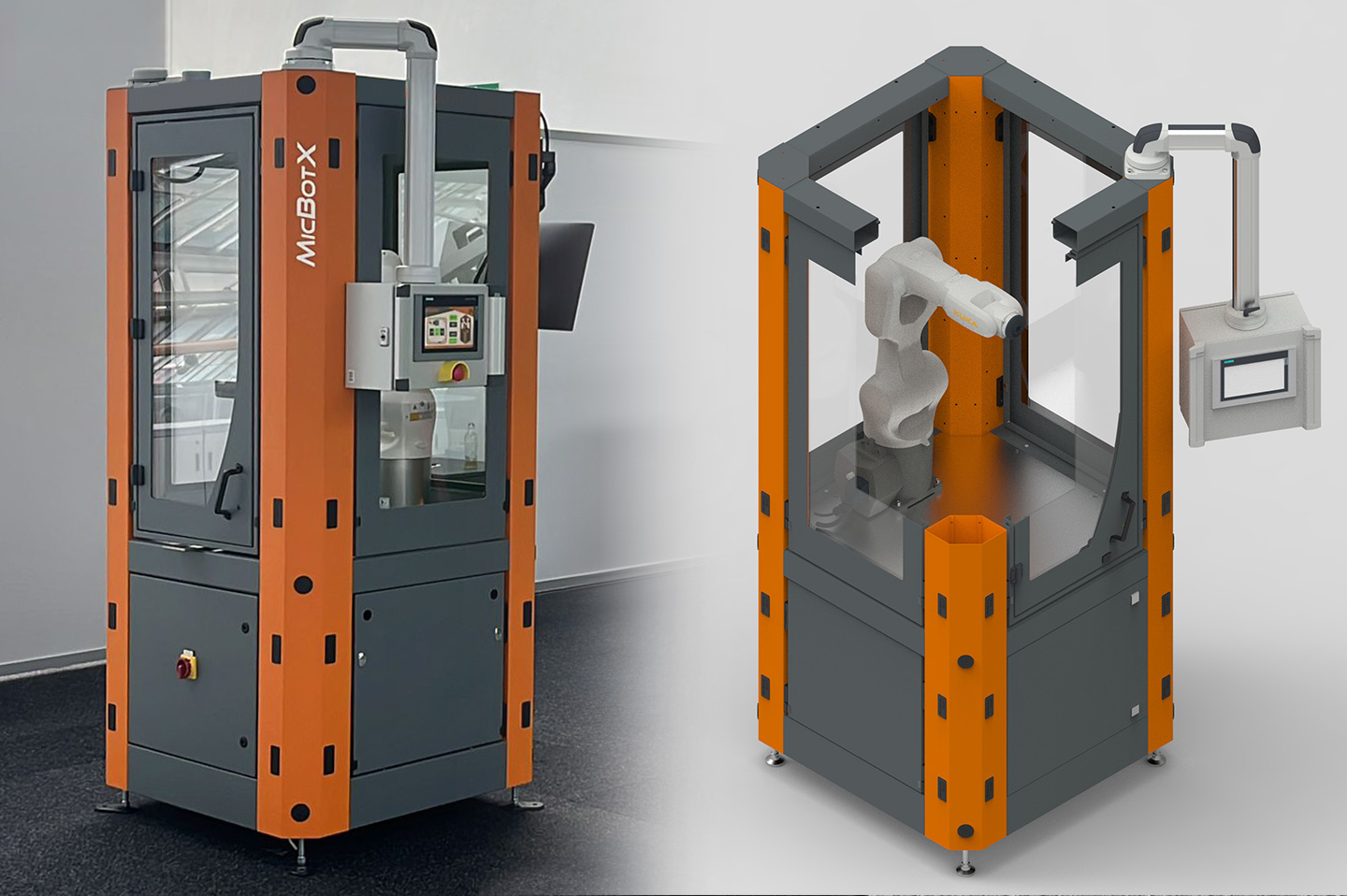

MicBotX: The modular automation solution for advanced manufacturing

Challenge

Automation gaps in machine tools and injection molding machines

Machine tools and injection molding machines are poorly automated. As a result, manual work steps are necessary, leading to longer throughput times, higher costs and an increased risk of errors. The lack of automation leads to:

- Increased personnel expenses. However, especially in times of staff shortages, vacancies are difficult to fill.

- Inefficiencies due to manual work steps.

- Outdated work processes that can no longer keep up with current market standards.

- On top of this, automation solutions are often expensive due to a lack of standardization.

Vision

Automation using a flexible robot cell

MicBotX comes to the rescue here: the robot cell features impressive flexibility and can be used quickly and cost-effectively to automate machine tools and injection molding machines thanks to its modular design.

An overview of the robot cell’s areas of application:

- Machine loading and unloading: Efficient loading and unloading of machine tools and injection molding machines for smooth production.

- Camera-assisted bulk material sorting: Precise bulk material sorting thanks to advanced image processing technology.

- Versatile automation solutions: MicBotX adapts flexibly to different requirements in assembly, packaging and other automated processes.

Solution

More efficient processes and shorter cycle times

MicBotX is efficient, flexible, precise and can be easily adapted to different locations. The modern robot cell takes production to the next level and thus offers a wide range of benefits for companies:

- Less downtime through automation.

- Increased efficiency through reduced or constant cycle times.

- Uniform tasks can be taken over by the robot cell; staff is relieved, and hard-to-fill vacancies are eliminated (counteracting staff shortages).

- State-of-the-art solution for increased competitiveness.

Challenge

Being able to use automation solutions flexibly

The future of manufacturing doubtlessly lies in simplifying processes through automation. However, retrofitting existing machines or purchasing new, automated machines is often very expensive, especially for machine tools and injection molding machines. This financial aspect keeps many companies from investing in automation. However, companies should bear in mind that foregoing state-of-the-art solutions not only results in higher personnel costs and more complex processes, but also increases the risk of losing touch with the competition in the long term.

Automation solutions are often inflexible

Although there are solutions on the market to simplify processes through automation, these solutions are usually not very flexible and can be difficult to integrate into existing machines. Often these solutions lack the necessary standardization while at the same time offering flexible adaptation options for different scenarios and environments. Consequently, most companies continue to rely on manual processes for their machine tools and injection molding machines – which leads to the following disadvantages:

- Companies cannot benefit from the cost and time advantages that automation brings.

- Employees have to carry out monotonous work processes. It increases the susceptibility to errors and vacancies are often difficult to fill.

- Important data that could easily be provided by an automated solution is either not collected at all or only with difficulty.

In short, flexible and modern automation solutions are needed here in order to benefit from the numerous advantages the modern working world has to offer.

Vision

Innovation meets precision: MicBotX redefines automation

MicBotX marks a new generation of automation solutions in manufacturing. It is a modular robot system that has been specially developed for loading and unloading machine tools and injection molding machines.

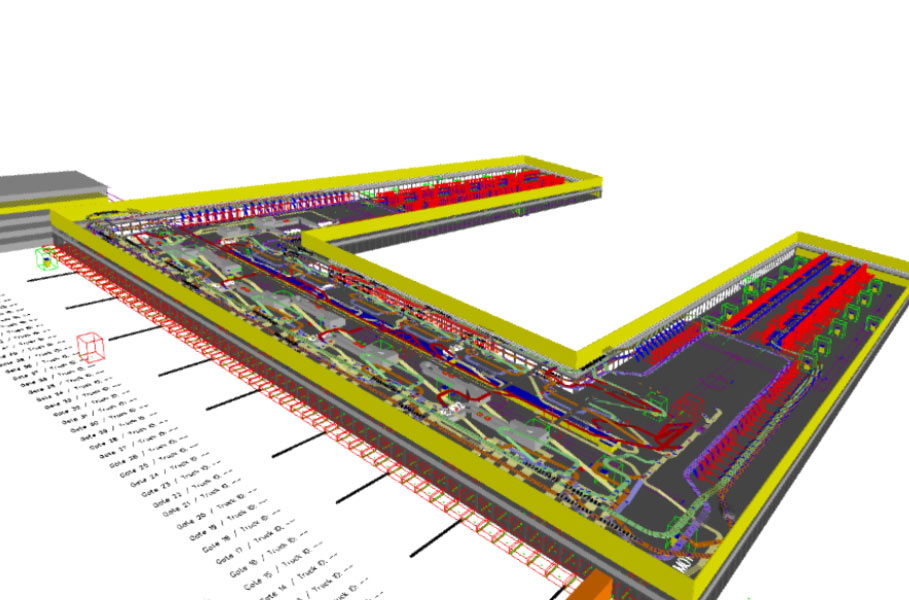

Discover a new dimension of efficiency thanks to intuitive operation and a modular design that adapts seamlessly to your operational requirements and different production environments. The solution is easy to integrate and offers flexible transportation options. In addition, we provide you with comprehensive support, from project planning to integrating the solution into your environment and, if required, also during operation.

Fields of application for MicBotX:

- Machine loading and unloading: Increased efficiency through automated processes.

- Camera-assisted bulk material sorting: reliable sorting thanks to advanced image processing.

- Versatile automation: flexibility in assembly, packaging and other processes.

MicBotX offers you a modern automation solution with many advantages – that our customers are already benefiting from in practice:

- Intuitive operation for efficient processes.

- Modular flexibility for dynamic production environments.

- Swift amortization through increased productivity.

- High-quality workmanship for lasting precision and reliability.

Solution

MicBotX: Your key to efficient and cost-effective production

You want to take your production to the next level? MicBotX is perfectly tailored to your company’s dynamic requirements. Integrating MicBotX into your manufacturing processes leads to a significant increase in production capacity, while the system’s flexibility ensures that you can respond to market changes without having to invest additional resources.

Flexibility and scalability

Production requirements are subject to rapid change, but with MicBotX you remain flexible at all times. Thanks to the modular cell sizes, you can quickly adapt the system to new production conditions. You benefit from scalability that allows you to expand or redesign your production line with minimal effort in order to adapt to changing market conditions and to make use of new opportunities.

Swift amortization: an investment that pays off

The decision for MicBotX is not just a decision for quality and efficiency, but also for cost-effectiveness. Due to the increased productivity, your investment will pay off quickly. This allows you to reinvest your capital in other areas of your business quickly in order to continue to grow and expand.

Cost and time savings

MicBotX offers a solution to one of the most common challenges in the manufacturing industry: the lack of personnel for repetitive and monotonous tasks. By automating these processes, you save on personnel costs and at the same time allow your employees to concentrate on more complex and value-adding activities.

Downtime reduction

Implementing MicBotX into your production process ensures that shift changes, breaks and unexpected downtime will no longer affect your manufacturing productivity. Automation enables virtually uninterrupted operation, reduces downtime and increases the overall efficiency of your systems.

Choose MicBotX and rely on a solution that will make your production future-proof. Take the next step towards an efficient and flexible production future – and get in touch with us now.