Become a part of digital industrialization and use your data strategically!

Challenge: Inefficient processes due to lack of transparency

Industry 4.0 connects machines and processes using technologies such as IoT. That way, devices and sensors communicate with each other and with the cloud – and generate data. You can use this data strategically for more efficient processes and better transparency. Many companies do not do this yet

The lack of data usage leads to:

- supply chain interruptions

- inefficient production planning

- inability to reduce production costs

- increased hazards operation

- increased machine downtime

- lower customer satisfaction

Vision: Improving processes by using historical data

Harness the power of your generated data with artificial intelligence (AI). By analyzing the data generated in the process and using AI methods, you can improve your processes and make them more efficient – and thus further develop your company.

This comprises:

- data collection – what data is available

- data analysis – discover patterns and anomalies

- data preparation – preparation and presentation

- training and evaluation – predicting trends with ML models

Improve the transparency and reliability of your processes. Optimize processes and automation to reduce downtime and inefficiency.

Solution: Use historical data for process optimization

Analyzing the accumulated data, combined with the use of AI methods, offers companies extensive advantages that go beyond traditional data management

These advantages at a glance:

- improved decision making

- improved strategic planning

- increased operation efficiency

- increased productivity

- improved customer experience

- supply chain excellence

Customer challenges: You want to benefit from digital industrialization – but you don’t know where to start?

Sensors and systems that consistently communicate with each other are the basis of the Internet of Things. This generates a wide range of process and production data. But in order to improve your processes, you need to use this data strategically, store it correctly and analyze it intelligently. We will assist you in this process. Find out more now!

Challenges through lack of data:

A lot of data contains important information – but it needs to be processed and analyzed correctly in order to identify patterns or clusters that can be useful to improve your processes. For example, you may be able to identify gaps in the process that are otherwise difficult to recognize and counteract them effectively. How can our experts support you in this? Find out more in the examples:

Example predictive maintenance:

Recognizing impending failures before they occur – this saves high costs and production downtime. Sensor data can contain information on the condition of tools, for example. If you use and process these historical data systematically, you can detect impending tool failure at an early stage and thus avoid potential machine downtime. This saves time and money!

Example predictive quality und quality optimization:

Ensuring and optimizing quality without having to carry out time-consuming quality checks – this reduces rejects and increases customer satisfaction. Many factors influence product quality: machine condition, environmental factors, raw materials, etc. Record the data and use it to improve quality. This will ensure good quality at all times, even with changing production conditions!

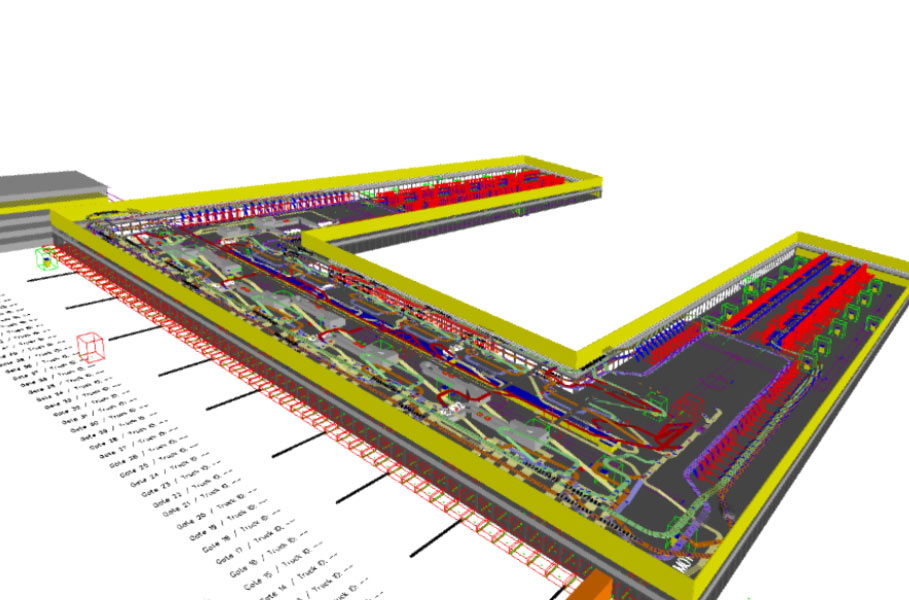

Example supermarket logistics:

Compiling, analyzing and correctly processing sales data from products in the supermarket – this is how you gain important information. For example, you will gain insights into which products are frequently sold or which tend to be slow sellers and which areas are best for placing offers. This allows you to optimize your supply chain and sell products in the best possible way – minimizing the risk of stocking slow sellers. This allows you to save money and operate more efficiently.

In conclusion, the following can be noted:

Data analysis is important in order to fully utilize the potential of the digital industry. Systematic data analysis and modeling give you deep insights into your processes. This allows you to identify potential for improvement and to optimize processes. The result: reduced costs, increased productivity and improved product quality. Derive forecasts for the future and remain competitive in the rapidly evolving manufacturing industry. With us, you can take full advantage of the benefits of digital industrialization. Contact our experts now!

The vision/solution: Analyze your data strategically to gain important business insights and optimize processes.

Data collection:

Goal: Providing the information you need to answer important questions, e.g. system behavior, analysis of company performance or other results. You can also predict future trends and thus develop target-oriented measures and scenarios. We will support you comprehensively in collecting the necessary data in the required quality and provide you with feedback. This allows you to uncover gaps and optimize your database.

Data analysis:

Goal: Discovering patterns, recognizing anomalies, testing hypotheses or checking assumptions. This allows you to gain important insights from your data. We will support you in the systematic use of visualizations for data analysis in order to discover patterns, detect anomalies, test a hypothesis or check assumptions. Visualizations such as histograms, scatter plots, box plots, whisker plots, line charts and bar charts are useful tools.

Data preparation:

Goal: Preparing data for machine learning models (ML) to solve a business problem. Data preparation comprises

- data cleansing: removing duplicate and incorrect values, incorrect data, inconsistent data types, incorrect entries, missing data and incorrect formatting.

- data integration: standardizing data from different sources.

- data transformation: changing the data format so that the data are suitable for machine learning (ML) / deep learning (DL) models.

We will support you in this and oversee the entire data process.

ML model training and evaluation:

Goal: Predicting future trends, measures and scenarios. This process includes the training of various machine learning (ML) / deep learning (DL) algorithms and the selection of the models with the highest accuracy.

We will accompany you along the entire data journey and can draw on extensive experience in various industries. Our experts in planning, IT and automation are familiar with your daily challenges and will develop a customized solution for you to use data systematically.

Added value for the customer: Analysis of the data (generated in the process) and implementation of AI methods for process improvement.

A lot of data is generated in production, e.g. by sensors on the machines, quality maintenance data, from process chains and systems.

Data analysis allows you to generate deep insights into your company that lie in your data and are not visible at first glance. This gives you valuable insights and allows you to use AI to increase your productivity by taking specific measures.

This may include:

Dealing proactively with machine failures.

Acting proactively instead of reacting passively – this saves time and money.

Better supply chain management.

Use predictive analyses to evaluate the costs and benefits of your products over time. By analyzing data from suppliers, transport companies and other sources, manufacturers can optimize their supply chains, reduce costs and improve delivery times.

Better understanding of customer requirements, preferences and behavior.

Develop products and services in line with your customers’ expectations. You will also gain insights into customer satisfaction and be able to identify areas for improvement.

Better strategic planning and improved decision-making.

You want to benefit from the advantages of Industry 4.0, save costs and time and remain competitive? Contact us now – we will accompany you on your way to optimized, modern production. Use your data systematically!

Who to contact at EDAG Production Solutions