From the Vision to Industrialization: We provide all-round support for startups

Challenge

Building factory structures – without data on either the product or location

Idea and vision already exist – but can start-ups make it from this point to the industrialization of the finished product? The pressure is on to quickly generate sales with the products and to scale efficiently. Because costs are mounting.

With start-ups, development of the product and industrialization are often parallel – and this leads to the following challenges:

- The absence of planning assumptions and/or frequently changing planning standards

- The constant revision of concepts which have already been finalized

- Data for the procurement of production and logistics equipment is missing

- Communication and decision-making structures are either missing or unclear

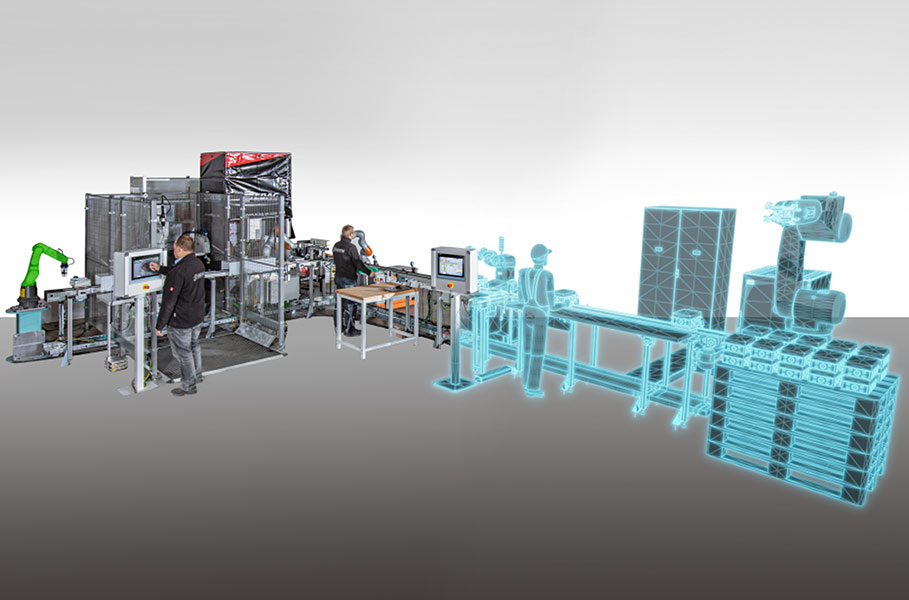

EDAG provides start-ups with support from the idea to the industrialization of their products.

Vision

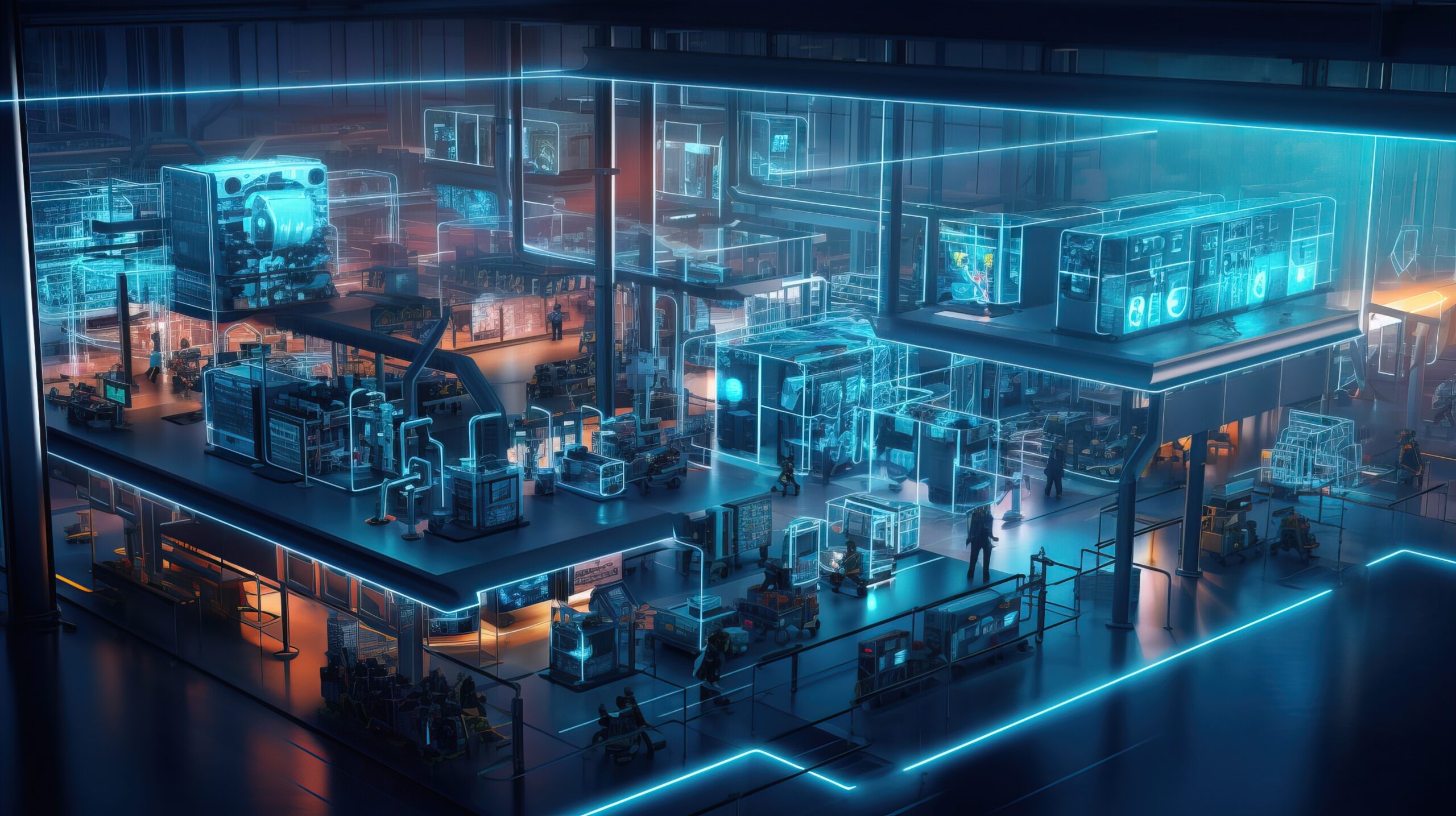

Flexibility leads to success: Benchmark solutions and agile project structures

Start-ups need to be flexible, as priorities change rapidly and frequently. In this “chaotic” environment, it is vital for structures and clear responsibilities to be created quickly. In order to ensure a speedy and reliable start of production, start-ups also have to plan and equip factories without having the initial data they actually need.

Here, too, EDAG can offer support – because the successful implementation of a project can only be achieved by:

- Using benchmark solutions

- Agile project structures

- Setting up clear communication channels

- Defining assumptions

- Structured change management

- Monitoring risks

Solution

You can quickly get production under way – even during the development phase

When it comes to the industrialization of products, agile project management and modern planning structures are essential. At EDAG, we have already been successful in supporting start-ups in this field, achieving crucial goals in terms of time, quality and adherence to budget. In cooperation with our customers, we have already successfully implemented the following points.

- Guaranteeing the scheduled start of production

- Coordinated and rapid integration of product changes and rapid responses to changing market conditions

- Key figure-based validation of the business case, for instance the achievement of budget targets for investments in equipment and personnel requirements

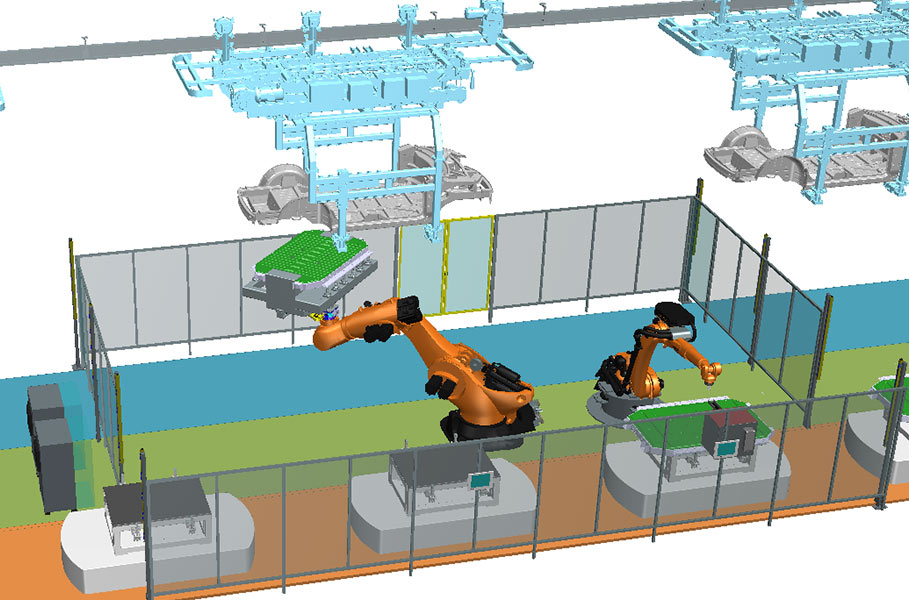

- Production scalability as a result of the optimum degree of automation

Challenge

Speed and quality: Industrialize your vision with EDAG

We are familiar with the challenges faced by start-ups: speed is of the essence. Especially if the young company is planning to introduce new products or derivatives to the market. If a new production facility is also going to be set up, there is even more to be taken into account – we keep an eye on the requirements and use our experience to support you through to the successful industrialization of your products and derivatives.

Challenge: Development of the product is not yet complete

The product idea is clear, but the product itself is still in the development phase. The product data, however, is a decisive parameter in efficient production and logistics.

This is a challenge we are familiar with. Whether you have a rough idea or a fully developed concept: we will plan your factory parallel to product maturity. Our experts at EDAG have extensive experience in all sectors and fields.

An absence of standards and planning assumptions

Particularly where start-ups are concerned, standards and production assumptions are often missing. But even for established companies intending to launch a new product line, there is often still room for improvement. Standards and assumptions are of fundamental importance when it comes to the efficient equipping of factories and production. The gaps are:

- Missing product data

- No or inadequate planning assumptions

- Missing standards for equipment and production

At EDAG, we help both startups and established companies to close these gaps, so ensuring that factories and production are modern and effectively equipped.

Vision

Make use of our expertise: Benchmark solutions and agile project management close gaps in information

What information gaps exist, and what is the status quo? This is the first question we ask, as this is the only way in which we can develop a successful project in structured cooperation with our customers. Our agile project management team works with you so that we can quickly integrate and monitor changes. The customized selection of benchmark solutions from reference projects and our own standards enables us to implement your project quickly, accurately and to the highest quality.

Benchmark solutions and agile project management

Time pressure is enormous: the project schedule needs to be adhered to. In addition, startups are often unable to wait for product data, standards and assumptions. Equipment must be procured, even if detailed product knowledge is not available. This is where we come in, with our know-how and access to customized references and benchmark solutions. These can be adapted for your project, allowing you to benefit from our extensive pool of knowledge. We also focus on flexibility: agile project management combined with established change management enables us to react quickly to changes and assess their impact. This means we can simply replace references and assumptions with your actual data – without any risk of jeopardizing or delaying the progress of the project.

We offer our customers:

- Tailor-made benchmark solutions

- Rapid response to changes

- Change management for consistent communication

Solution

Fast, precise and within budget

Even if things have to move quickly, there must be no compromise on quality and the budget must be adhered to. In addition, we guarantee the defined development of a factory structure (ramp-up plan) by using made-to-measure automation solutions. Benefit from professional cooperation on equal terms, and from our comprehensive expertise in all sectors and fields.

Speed

The product needs to be produced and brought to market as quickly as possible. We achieve this by saving time in the planning stage by using references and benchmark solutions – for both the processes and the necessary equipment.

Quality

We ensure high quality by means of risk management adapted to the project and quality gates quality gates based on the schedule. This allows deviations to be identified at an early stage and countermeasures to be defined and implemented accordingly.

Adherence to budget

For start-ups in particular, not exceeding the set budget is extremely important. Continuous monitoring of outgoings is a key factor here. In our projects, we consider both the current budget situation and the outlook, so that deviations can be identified at an early stage and specific measures initiated as necessary.

We do this by progressively replacing initial reference estimates for equipment costs with concrete supplier offers – either from your network or ours. Should budgets be exceeded, we work with you to define suitable cost-cutting measures, and then implement these without delay.

Ramp-up

We guarantee our customers’ ramp-up targets by implementing automation solutions. The important thing here is not so much maximum as optimum automation solutions tailored to your needs These include:

- Identifying the optimum time for replacing manual with automated concepts

- Market analyses for the selection of customized solutions

- Supplier management from initial contact to commissioning

We are your all-round partner and assist both startups and established companies in the industrialization of their product ideas. No matter which phase you are currently involved in, our experts are there to help with a plan specially designed for you. We can provide our expertise from the very outset – immediately and with pinpoint accuracy.

Contact us now and turn your vision into a marketable product!