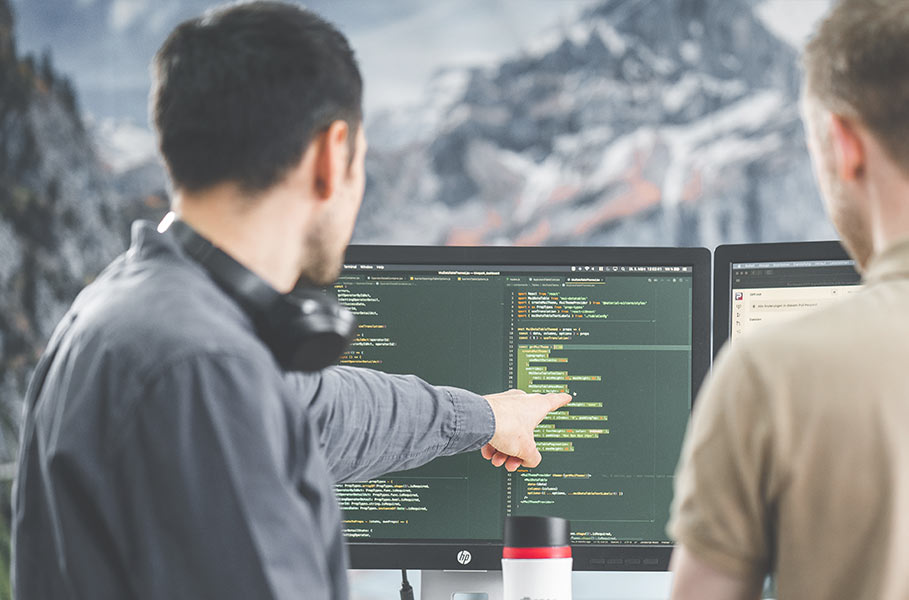

COMBINATION OF PRODUCTION, IT AND SOFTWARE KNOW-HOW

Companies in global competition are faced with stringent productivity and efficiency requirements and continually increasing (plant) complexity. Digitalization and production networking play an important role when it comes to addressing these issues. For successful implementation here, it is essential to take an all-round view of the production system. With its many years of expertise in product and production engineering and its comprehensive IT know-how, EDAG Production Solutions creates the basis for the digitalization of your production.

Effective validation with EDAG Production Solutions

We assist you with the development of your production processes and their validation, automation and optimisation – regardless of the complexity of your processes. In doing so, we use state-of-the-art methods and technologies: from material flow simulation, virtual commissioning and the digital twin to instrumentation and control engineering. Our goal is smart manufacturing, where big data solutions make production optimisation possible, and productivity requirements can be met by utilising real-time monitoring and predictive maintenance.

Effective validation with EDAG Production Solutions

We assist you with the development of your production processes and their validation, automation and optimisation – regardless of the complexity of your processes. In doing so, we use state-of-the-art methods and technologies: from material flow simulation, virtual commissioning and the digital twin to instrumentation and control engineering. Our goal is smart manufacturing, where big data solutions make production optimisation possible, and productivity requirements can be met by utilising real-time monitoring and predictive maintenance.

Services for digitalisation and networking in production

- Competence in automated, integrated engineering process with material flow simulation, digital twin and virtual commissioning

- Implementation of intelligent automation and flexible robot systems for process-optimised production plants

- Development and integration of cyber-physical system (e.g. MOM/SCADA/MES/energy monitoring)

- Big data solutions for production optimisation, Quality management, predictive maintenance and real time information management

Everything from a single source

We are at your side with our holistic approach and know-how throughout the entire project: from the production development process through the actual automation of the plant and integration of the control systems, to the extraction of measures from big data and the realisation of optimisation potentials. At every phase, you benefit from the way in which we closely interlink IT with our expertise in the field of production plants and processes and our product know-how. Let’s talk about your project now!

Everything from a single source

We are at your side with our holistic approach and know-how throughout the entire project: from the production development process through the actual automation of the plant and integration of the control systems, to the extraction of measures from big data and the realisation of optimisation potentials. At every phase, you benefit from the way in which we closely interlink IT with our expertise in the field of production plants and processes and our product know-how. Let’s talk about your project now!

OPTIMIZATION OF PLANT DEVELOPMENT

WITH SMART SOFTWARE PRODUCTS

Without software, innovation in plant development is no longer conceivable. It is frequently the software that makes all the difference.

Under our monobrand iSILOG, we develop, implement and market software applications that enable cross-discipline communication and provide optimal support for users. They facilitate the complete virtual development of machines and plants through to the representation of digital twins in production.

Find out more about our software products for production.

ADVANTAGES FOR YOU, THE CUSTOMER

- Safe start-up and high productivity

- Flexibility and increased efficiency

- Transparency and short response times

- Improved quality

Digitalisation & networking in production REFERENCES

Who to contact at EDAG Production Solutions

Michael Brugger

Senior Head of Department Digitalisierung Smart Factory

E-Mail: michael.brugger[at]edag-ps.com

Tel: +49 (0) 89 1500109-814

Jens Weiler

Head of CA Consulting & iSILOG

E-Mail: jens.weiler[at]edag-ps.com

Tel: +49 (0) 89 1500109593